Plate ígwè na-eguzogide iyi:

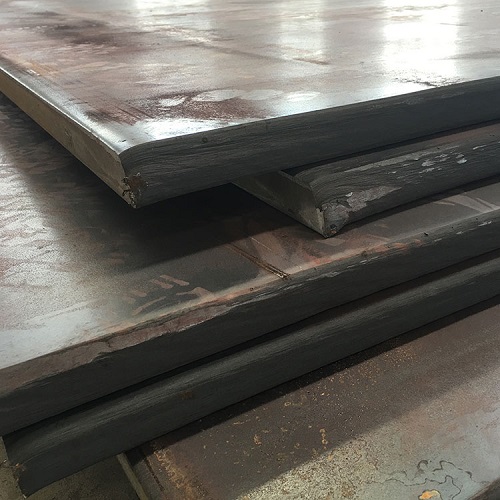

(1) NM360 (uwe na-eguzogide 360)

Ịkpọ aha: N bụ nguzogide (nai) M bụ mkpụrụedemede pinyin nke mbụ nke mkpụrụedemede China abụọ maka egweri (mo), na 360 na-anọchi anya nkezi Brinell siri ike nke efere ígwè a.

Ọgwụgwọ okpomọkụ: iwe ọkụ dị elu, quenching + tempering (quenching and tempering)

Ngwa: NM360 eyi na-eguzogide ígwè mpempe akwụkwọ na-ọtụtụ ebe na-eji Ngwuputa ígwè, coal Ngwuputa ígwè, gburugburu ebe obibi

A na-ejikwa ya dị ka ígwè nrụpụta ike dị elu na ike mkpụrụ ≥ 700MPa.Ọ bụ isi inye nchebe maka oge ma ọ bụ akụkụ ndị kwesịrị ịdị na-eguzogide iyi, iji mee ka akụrụngwa nwee ogologo ndụ, belata oge mmezi nke nrụzi na-akpata, ma belata ntinye ego n'otu aka ahụ.

Arụmọrụ: Mkpụrụ ahụ karịrị 800, na ike nhịahụ karịrị 1000.

(2) NM400

NM400 bụ efere ígwè na-eguzogide ike dị elu.NM400 nwere nnọọ elu n'ibu ike;ya n'ibu Njirimara bụ 3 ka 5 ugboro nke nkịtị ala alloy ígwè Ibé akwụkwọ;ọ pụrụ budata melite eyi iguzogide nke n'ibu metụtara akụkụ;si otú ahụ na-emeziwanye ndụ ọrụ nke igwe na ibelata ụgwọ ọrụ mmepụta ihe.Isi ike nke ngwaahịa a na-abụkarị 360 ~ 450HB.Ọdabara structural efere efere maka nhazi na n'ichepụta nke eyi na-eguzogide na-adịghị ike maka ogbunigwe na dị iche iche na-ewu ígwè ọrụ.

A na-eji NM400 nchara mpempe akwụkwọ na-eguzogide ọgwụ n'ọtụtụ ebe na igwe ihe owuwu, igwe Ngwuputa, igwe Ngwuputa kol, igwe nchekwa gburugburu ebe obibi, igwe igwe na akụkụ ngwaahịa ndị ọzọ.Onye na-egwupụta ihe, onye na-ebu ibu, efere bọket bulldozer, efere ihu, efere akụkụ akụkụ, agụba.Mpempe ahịhịa, agụba.

(3) Mn13 (ọkọlọtọ elu manganese ígwè)

Mn13 bụ nnukwu ígwè na-eguzogide manganese (HIGH MANGANESE STELL SCRAP), nke bụ nhọrọ kacha mma n'etiti ihe ndị na-eguzogide iyi dị ka mmetụta siri ike na akwa ihe mkpuchi.

Enwere njirimara abụọ kachasị ukwuu nke ígwè manganese dị elu: otu bụ na ka mmetụta dị n'èzí na-abawanye, nke ukwuu na-eguzogide oyi nke oyi akwa ya.Mgbe a na-emetụta ya, isi ike elu ya ga-abawanye ngwa ngwa site na HB200 ruo n'elu HB700, si otú a na-emepụta oyi akwa elu na-eguzogide ọgwụ.The austenite dị n'ime oyi akwa nke efere ígwè ka na-ejigide mmetụta siri ike dị mma;nke abụọ bụ na site n'iji nwayọọ na-eyi oyi akwa oyi akwa siri ike, ọkwa ọhụrụ na-arụsi ọrụ ike ga-anọgide na-etolite.

Mn13 akpọrepu ígwè efere nwere magburu onwe eyi na-eguzogide mmetụta siri ike na oke nrụgide, agaghị agbaji n'oge a na-eji ya, ma nwee ihe eji arụ ọrụ dị mfe dị ka ịcha, ịgbado ọkụ na ịgbado.

Igwe ihe nkedo chromium dị elu eji eme omenala nwere ezigbo nguzogide iyi naanị maka ịkwagharị akwa.Mn13 akpọrepu ígwè efere nwere ike ibelata ojiji nke iyi akụkụ nke akụrụngwa nke ọma, na-azọpụta akụrụngwa na-akwụ ụgwọ, na melite asọmpi nke emechara ngwaahịa.

Otú ọ dị, nkwụsi ike nke ígwè manganese dị elu na-egosi ịdị elu ya naanị n'okpuru ọnọdụ zuru ezu iji mepụta ike ịrụ ọrụ, ọ dịkwa njọ n'ọnọdụ ndị ọzọ.

Ihe a na-ahụkarị nke Mn17 na-eyi akwa manganese dị elu bụ ịbawanye ụba nke manganese na ndabere nke ígwè Mn13, nke na-eme ka nkwụsi ike nke austenite dịkwuo mma ma na-egbochi mmiri ozuzo nke carbides, si otú ahụ na-eme ka ike na plasticity nke ígwè ahụ dịkwuo mma ma melite ọrụ ahụ. ike ike nke ígwè.na mgbochi abrasion.Dịka ọmụmaatụ, ndụ ndụ ndụdụ ụgbọ okporo ígwè ZGMn18 ejiri na ugwu dị 20% ~ 25% karịa nke ZGMn13.

Akara ule na oke ngwa nke nnukwu manganese ígwè a na-ejikarị na China bụ: A na-eji ZGMn13-1 (C 1.10% ~ 1.50%) maka akụkụ ndị nwere mmetụta dị ala, a na-eji ZGMn13-2 (C1.00% ~ 1.40%). A na-eji akụkụ nkịtị, ZGMn13-3 (C0.90% ~ 1.30%) maka akụkụ dị mgbagwoju anya, na ZGMn13-4 (C0.90% ~ 1.20%) na-eji akụkụ dị elu.Ọdịnaya manganese nke ọkwa nchara anọ dị n'elu bụ 11.0% ruo 14.0%.

Maka ịgbado ọkụ na ịrụzi, austenite dabeere manganese-nickel electrodes (ụdị D256 ma ọ bụ D266) kwesịrị họrọ, na ogologo na mkpa nkọwapụta, φ3.2mm × 350mm, na elu mkpuchi bụ alkaline.Usoro ọrụ na-anabata njikọ azụ DC, obere ugbu a, arc na-adịghị ike, obere bead ịgbado ọkụ na ọtụtụ akwa ịgbado ọkụ, ma na-edobe obere okpomọkụ na obere okpomọkụ.Tie ihe mgbe ị na-agbado ọkụ iji kpochapụ nchekasị.A ghaghị achọpụta nkedo dị mkpa.Flash ịgbado ọkụ (Swiss GAAS80/700 flash ịgbado ọkụ igwe) ma ọ bụ MAG ịgbado ọkụ (dị ka Nissan YD-S-500) nwere ike ji mee ihe dị mkpa ịgbado ọkụ, nke nwere ike n'ụzọ dị irè hụ na ịgbado ọkụ onuete n'ibu Njirimara.

Ihe mgbakwunye 1: Echiche nke isi ike

Isi ike bụ ndeksi arụmọrụ iji tụọ nro na ike nke ihe.Enwere ọtụtụ ụzọ maka ịnwale ike siri ike, ụkpụrụ ndị ahụ abụghị otu, na ụkpụrụ esiri ike na ihe ọ pụtara abụghị kpọmkwem otu.Nke a na-ahụkarị bụ static load indentation method hardness test, ya bụ Brinell hardness (HB), Rockwell hardness (HRA, HRB, HRC), Vickers hardness (HV), roba plastic Shore hardness (HA, HD) na ndị ọzọ siri ike uru ya na-egosi ikike nke elu nke ihe iji guzogide ntinye nke ihe siri ike.Isi ike abụghị ọnụọgụ anụ ahụ dị mfe, kama ọ bụ ndepụta arụmọrụ zuru oke na-egosipụta ngbanwe, plasticity, ike na ike nke ihe.

Isi ike nke nchara: Aha koodu nke hardness metal bụ H. Dị ka usoro ule siri ike dị iche iche si dị, enwere okwu ndị a.

● Okwu ọdịnala gụnyere Brinell (HB), Rockwell (HRC), Vickers (HV), Leeb (HL) hardness, wdg, n'ime nke HB na HRC na-ejikarị eme ihe.

●HB nwere ọtụtụ ngwa ngwa, a na-ejikarị ya eme ihe mgbe ihe dị nro, dị ka ọla ndị na-abụghị ígwè, ígwè tupu ọgwụgwọ okpomọkụ ma ọ bụ mgbe annealing.HRC dabara adaba maka ihe ndị nwere isi ike dị elu, dị ka ike ọgwụgwọ okpomọkụ, wdg.

Ihe dị iche n'etiti ha abụọ bụ na nyocha nke ndị na-anwale ike siri ike dị iche.Ihe nyocha nke Brinell hardness tester bụ bọọlụ nchara, ebe nyocha nke Rockwell hardness tester bụ diamond.N'okpuru ọnọdụ ụfọdụ, HB na HRC nwere ike gbanwere site na-ele anya na tebụl.Enwere ike ịdekọ usoro mgbako echiche ya dịka: 1HRC≈1/10HB.

●HV-adabara maka nyocha microscopic.Vickers hardness (HV) na-pịa n'ime elu nke ihe na-erughị 120kg na diamond square cone indenter na a vertex n'akuku nke 136 °, na n'elu ebe nke indentation olulu nke ihe na-ekewa site ibu ibu. uru, nke bụ Vickers hardness value (HV).A na-ekpebi hardness Rockwell (HR-) site na omimi nrụrụ rọba indentation iji chọpụta nrịbama uru ike ike.Ọ dị mfe ịrụ ọrụ, ngwa ngwa na nghọta, ma dabara adaba maka mmepụta oke.

Mgbakwunye 2: Nchara na-eguzogide iyi nke a na-ejikarị

Ụlọ (Wugang, Xingang, Wuhan Iron na Steel, Nangang, Baosteel): NM360, NM400, NM450, NM500, NR360, NR400, B-HARD360, B-HARD400, B-HARD450

Igwe anaghị agba nchara Swedish: HARDOX400, HARDOX450, HARDOX500, HARDOX600, SB-50, SB-45

Igwe anaghị agba nchara German: XAR400, XAR450, XAR500, XAR600, Dillidur400, Dillidur500

Igwe anaghị agba nchara nke Belgium: QUARD400, QUARD450, QUARD500

Igwe anaghị agba nchara French: FORA400, FORA500, Creusabro4800, Creusabro8000

Igwe anaghị agba nchara Finnish: RAEX400, RAEX450, RAEX500

Igwe anaghị agba nchara Japanese: JFE-EH360, JFE-EH400, JFE-EH500, WEL-HARD400, WEL-HARD500.

Oge nzipu: Jan-29-2023